What comes to your mind when we ask you to name a few ancient fabrics of our country? You would say cotton, wool, silk are the closest to our roots. But what about the artery that is still obscure to the world. The designs and work that transform that plain fabric into a notable work of art. Earlier people used to only acknowledge a cloth by its fabric and not by its craft, but now they have started inclining towards handicraft and small textile industry crafts, to consider it.

One such craft that we are going to talk about is pochampally ikat. It is basically a dying technique of geometrical patterns on a cloth, more specifically sarees. Women have been wearing this print sarees since the 1800's. South Indian towns situated between Vijayawada and Chennai, were the earliest weaving centres of this craft. Usually it is also known as Pogudubandhu and chutki in Telangana, which is the parent district of this ancient ikat weaving.

To have more insights on this craft, we roped in Dipika, from Illusion cult, an engineer by profession residing in Abu Dhabi. She happens to be a handloom lover and a saree enthusiast.

Who better than her would know how to rock the latest designs right?

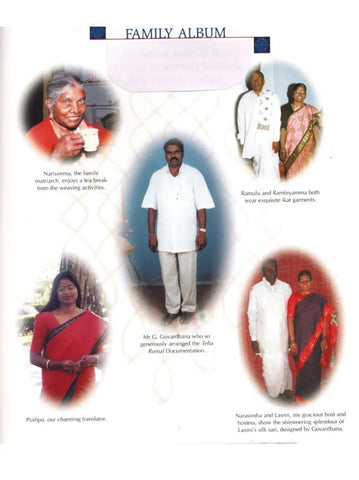

She interviews the artisan , Padma Shri Mr. Govardhan ji, from puttapaka village, who has been working on this for years continuing a family legacy.

“What fascinates me the most is how ikat is the same on both sides, and how beautifully hand woven it is. There is no colour bleeding in the real pochampally ikat, and that's the real beauty of it”

Dipika

Govardhan ji, how long have you been associated with this craft?

It is my family business, so technically, forever. I saw my father and his father, my mother, my older brother do it. We first started weaving on a handkerchief. I was selected by the ministry of textile and served my job for 23 years, soon realising that I needed to incline more in our family business. Hence, I took a voluntary retirement and joined my brothers in our family business.

Earlier, ikat was produced in 800-1000 looms for 30 years in Puttapaka, Telangana. The pochampally ikat are displaced in various countries like London, France, Italy naming a few. Because of this, it attracted marketing from different department stores of these countries.

How old is ikat?

Ikat first came from Gujarat moving forward to Orissa and Andhra Pradesh. The ikat designs and motives of all these three states are different and unique in their own way. Countries like Malaysia, Thailand and Indonesia also produce ikat. So we can say tentatively that it has been about 100 years.

What is different in Pochampally ikat?

Ikat in general is a very ancient print. The yarns are dyed before being woven into a cloth. Its beautiful motifs are printed on both the sides, and can also be worn multiple ways. It is also very profitable, It has money in every single stage in its making. So we can say it’s just not a handicraft, it’s a mind craft. It’s unique because of the creation process.

Usually the process is considered very arduous and time consuming, but rightfully, is magnanimously appreciated worldwide because of it’s preciseness.

Ikat fabric work depends on two major parameters, dying and weaving. “Ikat '' means dying, and there are two types of dying, Single Ikat and Double ikat. Bundles of Yarns are tightly wrapped together to achieve desired patterns. Let's break down the process a little bit more as explained by Govind Ji.

How do you design it?

When it comes to dying, not all can make valuable original coloured ikat as it is not only time consuming, but its entire colour process depends on the type of pattern being used. Primarily we use natural colours, no heat setting or uneven colouring. What we should avoid is direct colouring. When the yarns are dyed and also dried, they are lined up on the loom to form a precise pattern. Just to delve more into how precise and arduous the process is, the weaver has to systematically dye the thread in exactly the same place and line it up on a loom in order to replicate the pattern.

Ikat weaving is of two types:

Warp

In this the weft yarns are all dyed a solid colour, and warp yarns are ikat dyed. The weft threads solidifies the colour and completes the fabric formation.

Weft

In this the weft threads are ikat dyed, as the pattern would be only formed as the weaving progresses.

Binders usually use 90 degrees of heat for cool dying. Irony right!

The ikat print is best done handcrafted and on silk and cotton cloth. On silk acid colours are used to bring out the best, as naphtha creates colour bleeding. To avoid colour bleeding at all sorts, soak the yarn in goat dung for one day and then again in castor oil seed and ginger powder. This way the yarn takes about 21 to process. Earlier in those days, natural colours were used like indigo colours, but due to new era, marketing techniques, and latest designs and demands, the colours which customers prefer are used. There is no particular restriction on how to work on. Creativity and flow is the key in creating ikat designs.

A DIFFERENT LOOK

Ikat is not just created in India, but also is found and created in various countries of the world like Endek is one ikat type from Indonesia, and just like this more, as spoken earlier. Famous international designers, for instance Oscar De la Ranta, also incorporate ikat with their western designs, so it is not just about sarees and traditional wear.

Govind ji, what according to you is the difference between Indian ikat and international ikat?

There is a very elaborated and evident difference in both the ikats and in all aspects. Let's take a few examples, Indian ikat has a massive production, whereas in the other countries, who produce ikat, it's rather slow, tedious or on demand. Then techniques used also happen to be different, we use tie-dye, they use Buddhist prints.

Did you know that the gamcha that the sheikh wears is actually made of thelia rulam which is made of pure woven ikat , to keep their heads cool in summers and warm in winters.

Also, real ikat would always have larger designs, and pure fabric, whereas in cheap ikat the prints would be digital, and cloth used would usually be polyester.

What is the difference between running fabric and a saree?

The most vital aspect here is the thickness of the yarn. Like in plain weave is easy and simple, but then multiple weaving might be arduous. Tentative width of a saree is 47-48 inches, and dress material is somewhere between 40-45 inches. Since there is no loom technique used, it takes a bit longer to prepare a set of clothes. Let's say sarees, around 24 sarees takes non-stop 2 months of preparatory work, plus additional 2-3 days of rest of the completion of weaving and more

“We are so grateful to Itokri, for allowing us a platform for our worldwide sales and also to showcase our vast variety of products. We truly cherish the support”

Padma Shri Mr. Govardhan

Master Artisan

Blogs you might also like:

Chitrika Artisan Producer Company - Crafting Collective Gain

Kanchipuram Weaving

Bengal Kantha Embroidery

Verified Purchase

Verified Purchase

Leave a comment (all fields required)