Artisan In Focus: Interview With Artisan Varun Pedana, A Pioneer Of Kalamkari Craft

Our artists are our pride. Along with bringing to you the masterpieces that are the epitome of grandeur, elegance, and beauty, our artisans work endlessly to preserve the traditional handicrafts of the country. At iTokri, we take pride in collaborating with skilled artists who bring the best to you from various parts of India.

This blog celebrates and honours one such skilled artist of Kalamkari.

In this blog, we have covered Varun Pedana, a Kalamkari art specialist who hails from the Pedana town of Andhra Pradesh.

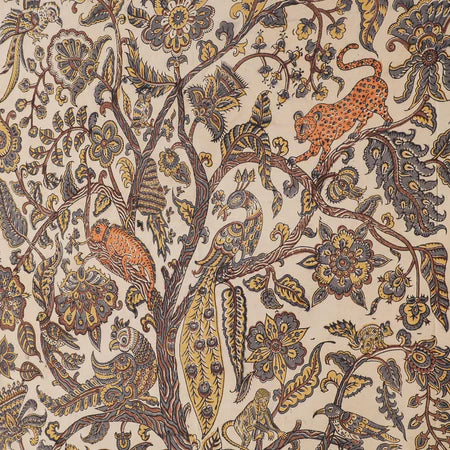

Kalamkari is a hand-printed or hand-block-printed cotton textile. The artist uses natural dyes to print the fabric. Kalam and Kari, which are derived from a Persian term, have the same literal meaning as pen and artistry, respectively. Flowers, peacocks, paisleys, and deities from the Ramayana and Mahabharata are the most used motifs in this ancient Kalamkari art form. In the past, people would visit different villages to tell tales, and some of them would even illustrate them on canvases. The art of telling stories gave birth to Kalamakari.

Let’s learn in detail what our artist, Varun Pedana has to say about this meticulous handicraft.

1. What is your name and where are you from?- My name is Varun Pedana and I belong to Pedana town, Andhra Pradesh.

2. What kind of handicrafts do you specialise in?- I specialize in natural colour block printing and Kalamkari handicraft.

3. How long have you been practising this craft?- I have been practising this art for nine years.

4. Is your family also involved in the same craft?- I acquired this art from my grandfather who started practising Kalamkari in the year 1970, later on, my father mastered the art from him and now I am doing it.

5. Can you describe the process you go through when creating a piece of your handicraft?Step 1: At first, we get the raw plain and powdered fabric from the nearby town.

Step 2: Before weaving the fabric, we degum the fabric, i.e., remove the starch from it by keeping it in water for 3 straight days, however, every 24 hours we change the water.

Step 3: Once the starch is completely removed, we do the Kalam treatment.

Step 4: Then we do the Myrobalan treatment, which is said to hold the natural dye to the cloth and prevent colour transfer.

Step 5: We source Myrobalan from the market, grind it into powder, and soak the powder in water for 12 hours.

Step 6: Then we refill the water, keep the naturally bleached fabric in the water solution for 15-20 minutes, and then dry it properly in the sun. The whole process takes us approximately half a day.

Step 7: After this, the fabric is ready for printing.

Step 8: We use black, alum and a red colour solution prepared in our unit itself with the help of an earthen pot. The black colour is prepared using salt water, iron waste, and jaggery in the earthen pot. The solution is left idle for fermentation for 21-30 days until the black colour appears. Alum is a mordant, used to create different colours shades, so whenever we need various colours we use alum. For instance, alum mixed with pomegranate juice gives a mustard colour, boiling alum with Manjistha gives a red colour and so on. We source Indigo colour from Tamil Nadu.

Step 9: After printing, we take the cloth to the flowing water, rivers, and canals, but during summers when there is no water around, we take it to Krishna River which is 70 km away from our unit.

Step 10: After that, we boil the fabric in a copper vessel.

Step 11: Post that we do the second colour filling.

Step 12: After washing one more time, the fabric is ready for stitching and modification.

For one fabric to get ready, it takes 15-20 days. In 2 months, we make around 1000-1500 meters of fabric. It varies as per the availability of artisans.

6. Where do you get your inspiration from?- I get my inspiration from old photographs of my grandfather’s work, catalogues, and related books.

7. What kind of materials do you prefer to work with?- I prefer to work with cotton and linen material.

8. Do you use traditional techniques or have you developed your own?- I employ mostly traditional techniques.

9. What challenges have you faced in your craft and how have you overcome them?- Artisans are not available on a regular basis and we have to go to nearby villages for flowing water, which villagers oppose.

10. Which is your favourite piece that you have created and why is it your favourite?- My favourite piece of work is the Tree of Life wall hanging, it was very challenging. It is my favourite as we employed 216 blocks as compared to 4-5 blocks in normal printing.

- Yes, I am the only one doing the craft along with my father.

12. Will you teach your children the same traditional craft?- Yes, of course, I will teach them from the very beginning.

13. How do you see the future of traditional handicrafts in India?- As most of the youngsters are leaving the villages and moving to urban areas for studies or employment, the future of handicrafts is in a bit of danger.

14. Are you involved in any initiatives to preserve and promote traditional handicrafts?- I do documentation of how we do the Kalamkari process so that it is available for people years after.

15. What advice would you give to someone who is interested in learning a traditional handicraft?- I will advise the budding Kalamkari artists to not leave practising the handicraft in between and keep patience if they want to grow. Traditional Indian handicrafts have a long way to go given its popularity worldwide.

16. How has been your association with iTokri?- Before iTokri, I didn’t have any platform which took bulk quantities from me. Also, working with iTokri, I get the freedom to experiment with the designs. My association with iTokri is a very good one.

Verified Purchase

Verified Purchase

Leave a comment (all fields required)